Arrow Energy, Queensland

Arrow Energy is one of the major players in the Australian Oil & Gas scene. Arrow delivers around 20% of the gas produced in Australia and takes the supply from 5 different gas fields in Queensland. When producing gas from a well, oil and water are always present as a by-product and need to be treated.

The Challenges

Ultraspin has worked closely with Arrow Energy over a number of years and has several systems on several sites. The issue on this site was that oily water resulting as a by-product of the gas production was being treated very crudely using gravity.

The oily water was being pumped into a large – 1.5ML tank where over a long period of time the oil began to break out of the water. There were several issues with this approach:

- Because the oil droplet size was relatively small, the tank wasn’t big enough to provide enough residence time for gravity to separate the oil out – one idea was to install more large tanks at significant cost

- The oil that did separate out formed a blanket layer on the top of the tank which prevented the water from evaporating – this led to the need to truck oily water off site, again at significant cost

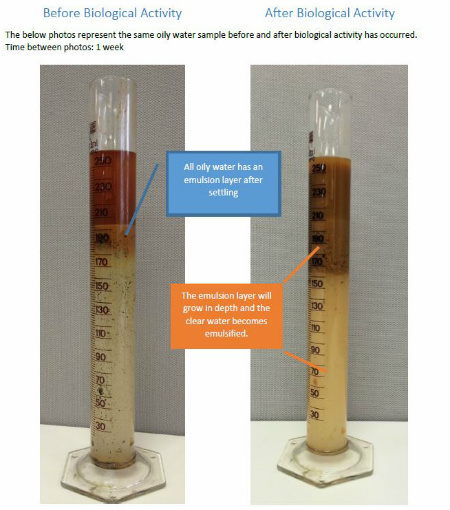

- The oil being left in contact with the water was a perfect environment for biological activity – bugs love to live in the interface between oil and water where they feed and create emulsified and dissolved oils which are very hard to treat

- The tank was in a relatively remote area which meant that power was an issue in the area, running 3 phase power to the area was going to be prohibitively expensive

The Outcome

The timelapse photo on the left was taken during the commissioning of the Ultraspin system and shows the oil being cleared from the tank, this took less than 24 hours and more than 15,000L of oil was removed. This cleared the surface of the tank to allow evaporation to occur.

In the scrolling pictures above you’ll see visual samples taken from the system after 6 months of operation, the analysis on these samples showed the inlet sample concentration was >1,200mg/L and the treated water that was being recycled back into the 1.5ML tank was 25mg/L – this is an impressive separation efficiency of 98% for very hard to treat water.

The video below shows the skimmer in action in the 1.5ML tank – this is our smallest skimmer and it’s done a great job of drawing oil in from all over a tank with a diameter of ~20m.